The Most Overlooked Part of Networking Is the One Everything Depends On

Tim Ralston, Regional Sales Director at INS | December 18, 2025

In industrial networking, everyone loves to talk about switches, security, wireless, and software. Those are important, but they are not where most problems actually start. After almost 30 years in this industry, I can tell you that the biggest issues customers face almost always come down to something far less flashy:

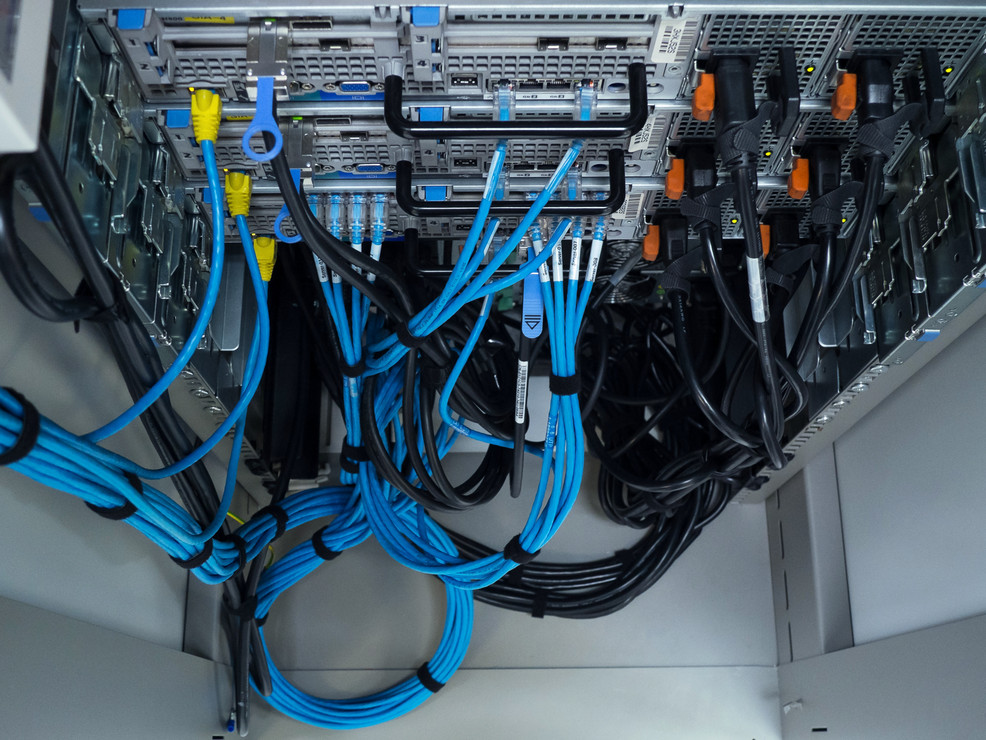

Layer 1. The physical infrastructure. The cables, connectors, patch panels, cabinets, and enclosures that everything else relies on.

When something goes wrong in a plant or a distribution center, people usually blame the switch or the software. But if you look deeper, the root cause is often the physical layer. That is the part of the network that gets ignored until something breaks, and by then, it is already costing time and money.

I have built a career on helping customers find those issues, fix them, and build networks that last. Layer 1 is not glamorous, but it is the foundation of everything else.

How I Learned to Care About the Details

I have a Mechanical Engineering degree, and began my career in the electrical industry helping electrical engineers make their products work. I learned the technical side the same way a lot of us did: by being in the field, listening, taking notes, and learning from people who had been doing this longer than me.

What made the difference in my career was simple. I paid attention. I did not pretend to know everything. And I learned quickly that if you understand the foundation—the cables, the power, the cabinets, the connectors—you can solve almost any networking problem someone throws at you.

That practical, hands-on mindset is still how I operate today.

Layer 1 Is the Nervous System of the Network

If you think about the human body, the nervous system carries the signals that make everything else work. Industrial networks aren’t much different. Switches and software might get the attention, but if the physical connections are bad, none of it matters.

I’ve walked into customer sites where the switches were top-of-the-line, but the patch cables were bargain-bin products bought off Amazon: cables that failed under the slightest stress. I’ve seen enclosures mounted in direct sunlight with zero airflow, turning into ovens that cooked every device inside. I’ve seen customers purchase adapters and connectors online that looked fine in the picture but were never designed for industrial environments.

Every one of these situations created downtime. Every one of them was preventable.

It is easy to overlook the basics. But in industrial networking, the basics determine everything else.

A Story Every Manufacturer Should Hear

Years ago, I was working with a customer when one of their switches went down. Everyone immediately assumed the switch had failed. They were ready to replace it. But something didn’t feel right, so we started digging.

The real issue had nothing to do with the switch. It was the patch cable. A single bad cable cost that facility hours of production. It was a perfect example of how small decisions, ones that feel inexpensive at the time, can create expensive problems later.

This is why I tell customers:

You cannot build a reliable network on unreliable components.

Cheap Parts Cost More Than People Realize

I understand the temptation to save a few dollars. I shop online like everyone else (yes, even Amazon). But industrial networks are not the place to cut corners. When customers buy the cheapest cabinet, the cheapest power supply, or the cheapest connector, the consequences always show up.

In the real world, that means:

- Heat damage

- Moisture infiltration

- Loose terminations

- Interference

- Shortened equipment life

- Hours spent troubleshooting the wrong problem

I have seen a single cheap component take down an entire line. I have also seen what happens when customers invest in the right materials from the beginning: fewer problems, easier maintenance, predictable performance, and far less downtime.

When you think about the cost of a production stoppage, saving five dollars on a connector doesn’t make sense.

The Problems You See Aren’t Always the Real Problem

One of the most common situations I run into is when customers assume a network issue is happening at the switch or in the software. They see a failure up high in the stack, so they start replacing gear or adjusting configurations.

Nine times out of ten, the real issue is physical. A kinked cable. A bad termination. A patch panel that was never grounded properly. A cabinet that overheated in the summer sun. An enclosure installed in the wrong location.

Layer 1 issues show up as Layer 3 symptoms

If you don’t know how to spot that, you can waste days chasing the wrong thing. This is where INS brings value. We help customers trace the problem down to the root, not just replace the piece that looks guilty.

Why Strong Infrastructure Makes Everything Easier

When the physical layer is done right, everything else gets easier. Devices connect consistently. Wireless performs better. Switches last longer. Troubleshooting becomes simpler. And expansions or upgrades stop being a guessing game.

A customer once told me, “I didn’t realize how many problems we were living with until they went away.” That’s the impact good physical infrastructure has. It removes the friction people have learned to tolerate.

That is also why I always encourage customers to think about airflow, power, environmental conditions, and mounting just as seriously as they think about models and speeds. Even the right switch in the wrong cabinet will never perform at its full potential.

Quality at Layer 1 makes the entire network stronger.

What I Tell Customers Every Day

If you want a network that works the way it should, not just today, but five years from now, start with the foundation:

- Choose quality components.

- Protect them from the environment.

- Terminate cables correctly.

- Use the right enclosures.

- Think about heat.

- Consider cable management.

These are not extras. They are the things keeping your plant running. You can buy the best switch in the world, but if the cable plugged into it is damaged or low quality, it won’t matter.

Final Thought: The Simple Things Make the Biggest Difference

If there is one message I hope customers remember, it is this: You cannot build a reliable network on bad physical infrastructure.

|

Layer 1 may not be glamorous, but it is the foundation for everything else you want your operation to do: reliability, visibility, mobility, AI, automation, or anything else on your roadmap. If you take care of the basics, the rest of the system will perform the way it should. And if you ever want help getting the foundation right, that is what INS is here for. |