How INS and Cisco Built a Zero-Downtime Network for Midstream Operations

When a critical infrastructure outage threatened 24/7 midstream operations, INS and Cisco stepped in. By modernizing aging networks and deploying a fully redundant PRP architecture, the team ensured that field-to-control-room data flows never skipped a beat. Today, the customer operates with confidence, knowing their network can handle whatever comes next.

It was a normal day at our customer’s midstream facilities across Oklahoma, Texas, and Louisiana…until a critical network outage occurred. Data stopped flowing and control-system alerts were triggered. Every minute of downtime could cost millions and disrupt the movement of natural gas, crude oil, NGLs, and carbon dioxide.

In this case, patching the network would not be enough. They needed a partner who could understand both their legacy systems and the modern technology required to prevent future failures. That partner was INS, working together with Cisco.

Performing a Network Assessment

INS began by conducting a full-field assessment in partnership with Cisco. Our team inspected the facilities, traced the network connections, and reviewed legacy protocols. What they found was a network that had been stretched over decades: some areas were strong, others were vulnerable, but the entire system was critical to operations.

The challenge was clear. This customer needed to design a solution that would modernize the network without interrupting ongoing operations.

Designing a Network That Can’t Fail

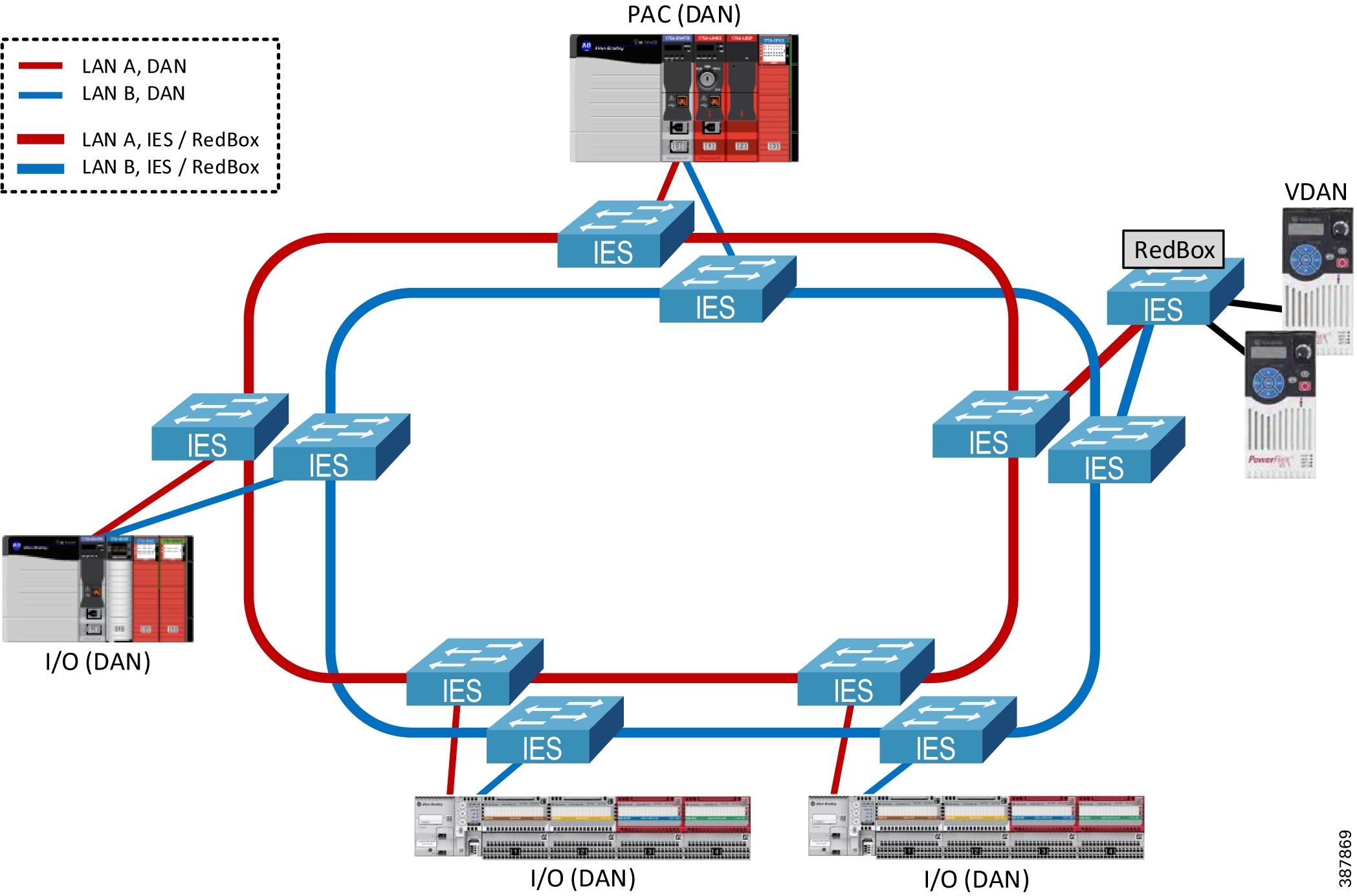

INS and Cisco implemented a fully redundant network using Parallel Redundancy Protocol (PRP), which uses two independent networks that send the same data at the same time. If one network fails, the other immediately takes over with zero milliseconds of downtime.

The team also integrated the new system with the company’s legacy protocols. Every connection was documented for operators in the field. INS provided post-project support and a roadmap for continuous modernization, ensuring the network could evolve alongside technology and security requirements.

With this approach, field operators could rely on the network to work every second, protecting both operations and revenue.

Moving from Vulnerable to Resilient

After the upgrade, the network became a reliable backbone for operations:

- Data flows continuously from field sites to control rooms

- Operators can troubleshoot, monitor, and update systems with confidence

- INS continues to provide support, guidance, and insight into emerging technology trends and security protocols

The outage that once threatened operations is now a story of resilience. Planning, expertise, and technology combined to transform the network into a system that can handle any challenge. With a network that never sleeps, this customer can focus on what matters most: moving product safely, efficiently, and without pause.

Discover how INS can create a resilient, future-ready network for your operations >>>