How INS and Celona Helped Del Conca Modernize Its Industrial Network with Private 5G

The Overhaul That Put Their Automation Back on Track

When you step into a Del Conca facility, you’re immediately struck by the scale and precision of their operations. Known for producing high-end marble for luxury hotels and residential spaces, Del Conca doesn’t just craft beautiful stone; they move tons of it across highly automated production lines, where every operation relies on precise coordination. Behind the scenes, automated guided vehicles (AGVs) play a pivotal role, lifting, moving, and positioning heavy marble slabs with minimal human intervention. But even in a facility this advanced, there was a challenge: their existing Wi-Fi network simply couldn’t keep up with the demands of an industrial environment.

This is where our strategic partnership with Celona came into play. INS was brought into the project not as an outside vendor, but as part of a coordinated, end-to-end solution. Celona had already laid the groundwork with an initial private cellular design, and together we refined, expanded, and engineered it into a fully realized network built for Del Conca’s industrial demands. That collaborative lifecycle, combining Celona’s technology and design expertise with INS’s industrial deployment experience, is what ultimately unlocked the reliability and performance Del Conca needed to keep its automated operations running without interruption.

When Wi-Fi Isn’t Enough: The Challenge of Industrial Connectivity

Del Conca’s plant is an extreme environment for wireless networks. Between the massive marble slabs, automated machinery, and complex workflows, Wi-Fi coverage was inconsistent. AGVs experienced intermittent disconnections, which could slow production and even compromise safety. For a facility where precision is everything, these disruptions put businesses at risk.

Del Conca wanted a solution that wasn’t just faster. It had to be reliable, fault-tolerant, and scalable. They needed a network that could seamlessly support AGVs indoors and outdoors, across the full span of the plant. Traditional Wi-Fi just couldn’t deliver on these requirements.

Proof of Concept: Designing a Powerful Industrial Network

INS and Celona knew that for a client like Del Conca, a proof-of-concept (PoC) was crucial. This wasn’t about presenting marketing slides, but about demonstrating tangible results. The team selected a single AGV to run on a private cellular network while the rest of the plant continued operating on Wi-Fi.

The results were clear and compelling:

- A single cellular radio outperformed dozens of Wi-Fi radios in coverage and reliability.

- The AGV maintained uninterrupted connectivity even in areas where Wi-Fi struggled.

- The demonstration gave Del Conca confidence that private cellular could not only meet but exceed their operational requirements.

This initial success paved the way for a full-scale deployment, showing that advanced private wireless isn’t just a theoretical solution. It delivers measurable performance improvements in real-world industrial environments.

Collaborative Design: Tailoring the Network to Del Conca’s Needs

With the PoC complete, we worked closely with Del Conca Celona to design a network that met the plant’s unique challenges. Celona had provided a baseline network architecture, and INS conducted a detailed site audit to refine the design, ensuring it was optimized for Del Conca’s production needs.

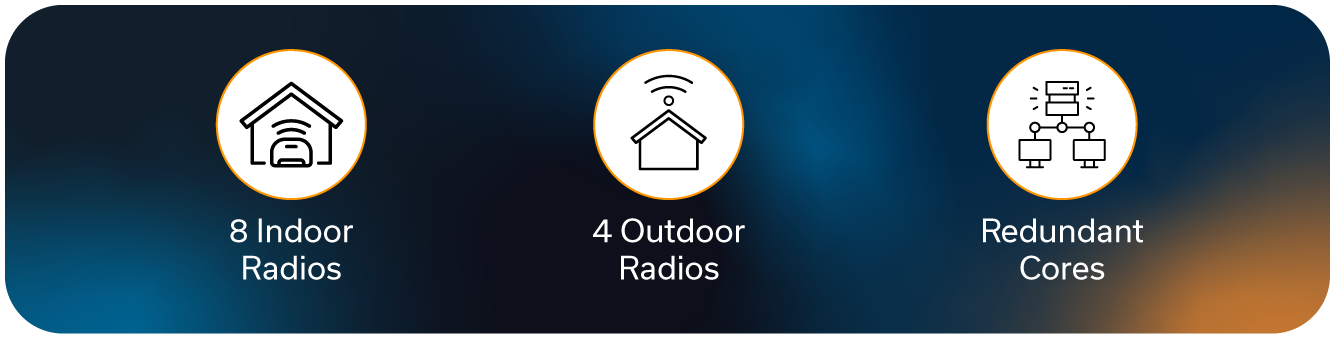

The resulting architecture included:

- Eight indoor radios providing full coverage across production areas, with redundancy to prevent downtime if one radio failed.

- Four outdoor radios, ensuring seamless transitions for AGVs moving in and out of the facility.

- Redundant cores geographically dispersed across the site, each with independent power supplies, to maintain connectivity even during power interruptions.

This design allowed Del Conca’s AGVs to operate continuously and safely, delivering the reliability that industrial automation demands.

Engineering Excellence: From Concept to Turnkey Installation

INS’s involvement didn’t stop at network design. The team provided full installation and implementation, covering everything from enclosures and cabling to radios and AGV connectivity. Our approach included:

- Properly rated copper and fiber cabling, installed and tested for industrial conditions.

- Fiber optic fusion splicing and optical time-domain reflectometry (OTDR) testing to ensure signal integrity.

- Shielded cables for EMI protection, safeguarding network performance in an electrically noisy environment.

INS’s installation teams are specifically trained for industrial environments, bridging the gap between advanced networking technology and rugged, real-world conditions. The result was a turnkey solution, fully operational and validated before Del Conca’s production resumed.

Testing and Validation: Every Detail Matters

INS follows a meticulous testing process to guarantee performance and reliability:

| Factory Acceptance Testing: In the lab, all network components and AGVs were tested against Del Conca’s operational requirements. |

Site Acceptance Testing: On-site validation ensured that the network performed flawlessly under real production conditions. |

This two-step approach confirms that every use case works as intended and allows the customer to witness and approve the system before going live. For Del Conca, this meant no surprises, no downtime, and full confidence in their new network.

The 4D Methodology: Discover, Design, Develop, Deploy

INS’s project methodology, which we’ve nicknamed the 4D approach, underpins every successful deployment:

Discovery

Understand operational needs, constraints, and objectives through site visits and client collaboration.

Design

Translate insights into detailed network architecture, including radio placement, IP schemas, and redundancy planning.

Develop

Configure equipment, stage radios, and conduct lab testing to verify functionality.

Deploy

Install the network, execute site acceptance testing, and ensure full operational readiness.

This structured process ensures consistency, quality, and reliability, no matter the scale of the deployment. For Del Conca, it meant a smooth transition from concept to fully operational private cellular network.

By moving from Wi-Fi to a private cellular network:

- AGVs operate reliably, reducing downtime and enhancing safety.

- Production efficiency improves, supporting high-volume marble processing.

- Del Conca gains a network that can scale and adapt to future technology needs.

For INS, the success of this project is a testament to our holistic approach: combining technical expertise, rigorous testing, and hands-on installation to deliver solutions that truly meet industrial demands.

Connectivity That Keeps Operations Moving

A reliable, well-designed private cellular network doesn’t just support operations, it enables them to thrive. Through a combination of proof-of-concept testing, tailored design, meticulous installation, and rigorous validation, INS and Celona helped Del Conca achieve a network that matches the scale, complexity, and ambition of their operations.

For industrial facilities facing similar challenges, Del Conca’s story illustrates one key principle: the right connectivity solution, executed well, changes the game.

Ready to elevate your industrial network? Connect with INS today to explore private cellular solutions that keep your operations running seamlessly.