Building a Smarter Pipeline: How Modern Industrial Networks Transform Energy Infrastructure

In the fast-paced world of energy infrastructure, modern pipelines are more than just steel and valves. They are sophisticated, data-driven networks that require precision, innovation, and resilience. For companies tasked with designing and building gas pipelines in challenging environments, integrating advanced operational technologies is no longer optional. It’s essential.

An INS project in the American Southwest illustrates just how far industrial networks have come and what it takes to modernize pipeline operations from end to end. The project involved a roughly 50-mile gas pipeline with multiple spurs and processing facilities, which presented unique challenges, from data-intensive operations in remote locations to tight production schedules and complex land management issues. For our engineering team, it was a chance to deploy cutting-edge solutions while rethinking how data flows across the pipeline ecosystem.

The Challenge: Data-Intensive Networks in Remote Locations

Modern pipelines are “smart” infrastructures. Sensors, meters, and remote terminal units (RTUs) continuously collect vast amounts of data, from pressure and flow rates to operational statuses of compressors and processing equipment. For this project, much of the pipeline traversed extremely remote terrain, including deserts with limited or no cellular coverage. Traditional communication methods, like standard cellular networks, simply couldn’t handle the heavy data volumes.

This created a unique engineering challenge: the team needed to design an operational technology (OT) network that could reliably collect, transmit, and analyze critical data across every segment of the pipeline, from extraction points to processing facilities and control rooms. The goal was not only to ensure uptime but also to enable advanced analytics, predictive maintenance, and real-time operational visibility.

A Clean Slate: Designing the Network from the Ground Up

One of the most exciting aspects of this project was the freedom to start with a clean slate. INS’s engineering team was asked to envision an entirely new industrial network without the constraints of legacy systems. This allowed us to focus on scalability, fault tolerance, and standardization—all critical factors when designing networks that support large, geographically dispersed assets.

At the heart of the design was the concept of edge computing. Edge devices, installed at wells, spurs, and other pipeline assets, handle the heavy lifting of data processing locally before transmitting information upstream. By processing data at the edge, the system reduces bandwidth requirements, improves latency, and ensures critical data is available even when network connections are intermittent.

To make the most of this architecture, we implemented a publish-subscribe protocol known as MQTT. Unlike traditional polling protocols, where servers constantly request updates from devices, MQTT allows devices to transmit data only when changes occur. This approach can dramatically reduce bandwidth usage, by as much as 80%, and increases the volume of actionable data available for decision-making.

Leveraging Standardized Industrial Hardware

The project also emphasized the importance of a common hardware framework across the pipeline network. Standardized routers, switches, and automation software simplified installation, reduced the number of spare parts required, and provided technicians with a consistent experience at every site.

For example, industrial routers at each site could run containerized applications, gathering and processing data locally before forwarding it to the main control facility and eventually the cloud. This approach not only streamlined operations but also created a foundation for future digital transformations, including digital twins—virtual models of the pipeline that provide real-time insights and predictive analytics.

Redundancy and Reliability: Ensuring Continuous Operation

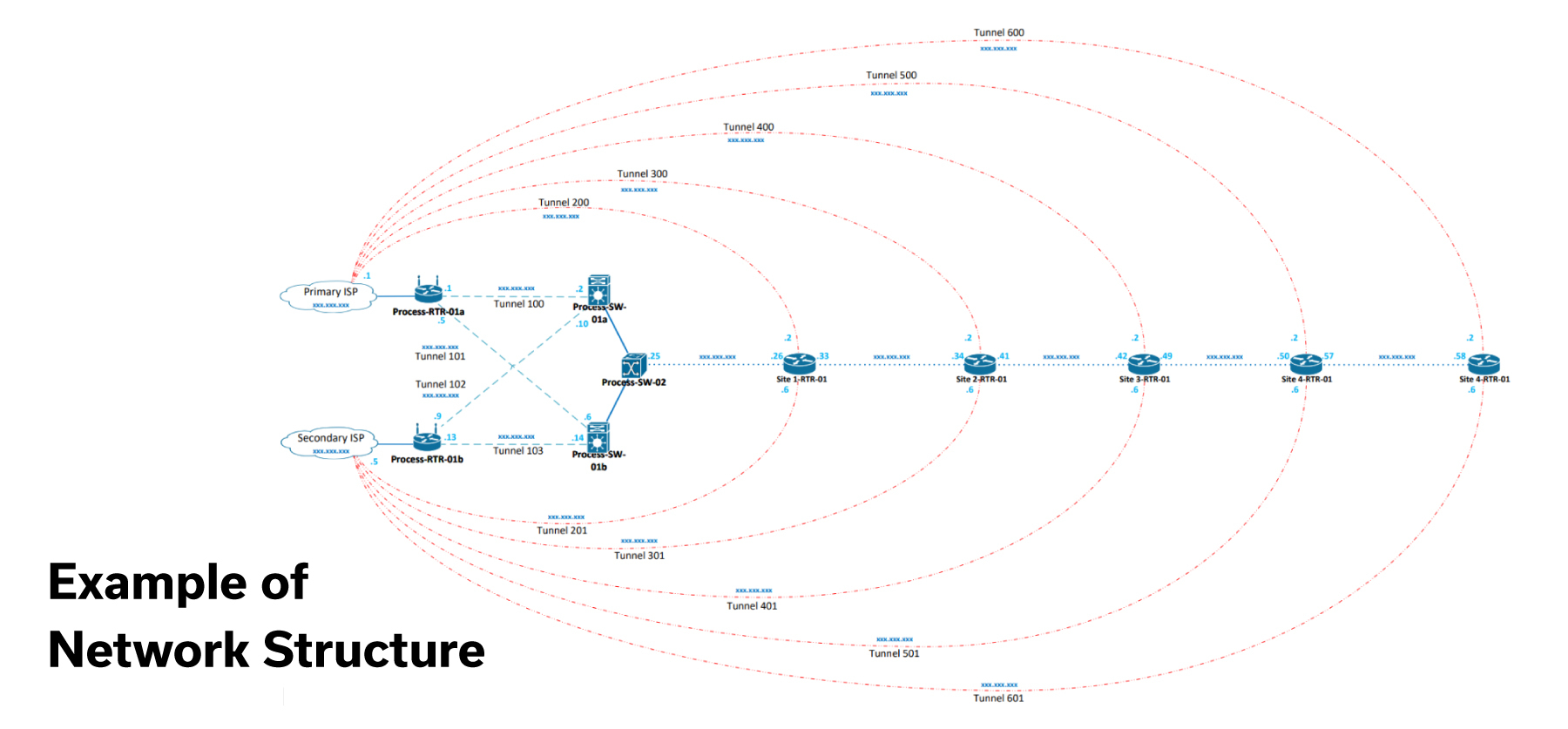

Pipeline operations are mission-critical, and downtime can be extremely costly. To address this, the network design incorporated multiple layers of redundancy. Critical points along the pipeline were equipped with backup links, failover systems, and resilient routing protocols.

For example, the network leveraged multiple Internet service connections, redundant primary radio backhaul, and redundancy at a local compressor station level if the downstream radios were powered down or unavailable. In addition, local network infrastructure was designed to tolerate single points of failure, allowing operations to continue seamlessly if individual devices or links went offline. This level of resilience was crucial for meeting the customer’s tight production schedules and contractual obligations.

Perhaps the most significant challenge was the timeline. The project had an aggressive schedule, requiring the rapid deployment of new wells, processing units, pipeline segments, and supporting infrastructure, all while maintaining data integrity and operational safety.

Every step of the engineering, testing, and validation process had to be carefully coordinated and expedited. Despite these pressures, the standardized network framework allowed our customer to deploy sites quickly and efficiently, minimizing delays and keeping the pipeline on schedule. The result was a reliable, scalable network that could grow alongside the customer’s operational needs.

Edge Computing and Digital Transformation

The use of edge computing represented a major step forward in industrial digital transformation. By processing data locally and transmitting only what was necessary to upstream systems, the network could handle far more data than traditional designs. Combined with digital twins in the cloud, the operator could monitor pipeline performance in real-time, optimize operations, and predict maintenance needs before issues became critical.

This approach mirrors trends seen across the energy sector. Increasingly, major operators are moving from legacy systems to modern, data-driven architectures that leverage edge computing, cloud analytics, and standardized hardware to achieve higher efficiency and reliability.

A Model for Industry 4.0 in Oil and Gas

The pipeline project exemplifies how industrial networks are evolving to meet the demands of modern energy infrastructure. Here are some key takeaways:

- Edge computing empowers data-driven operations: Processing data at the source reduces bandwidth usage and improves real-time insight.

- Standardization simplifies deployment and maintenance: Uniform hardware and software reduce complexity across sites.

- Redundancy ensures reliability: Multiple failover systems maintain uptime and protect against unexpected failures.

- Digital twins enhance visibility: Virtual replicas of physical assets allow predictive analytics and operational optimization.

- Clean-slate designs enable agility: Networks built without legacy constraints can be deployed faster and scale more easily.

This project also highlighted the importance of collaboration and adaptability. Working in remote environments with tight schedules requires close coordination among engineering teams, operators, and vendors. Planning for redundancy, edge computing, and scalable architectures from the outset ensures that networks can handle both expected and unforeseen challenges.

As more companies embrace Industry 4.0 technologies, networks like this one will become the standard rather than the exception. Edge computing, standardized infrastructure, and digital twins are not just buzzwords. They are practical tools that allow energy operators to improve efficiency, reduce risk, and make data-driven decisions in real-time.

This project serves as a model for how innovative engineering teams can transform pipeline operations, even under challenging conditions. By combining advanced technology with thoughtful design, companies can achieve resilient, scalable, and future-ready networks that meet the demands of modern energy production.

Ready to turn your network into a powerhouse? Let’s build smarter, faster, and more reliable pipelines together.