Beverage Manufacturing & Distribution Network Modernization Project

Driving Efficiency and Uptime Through IT/OT Convergence

Customer Overview

A cooperative manufacturing and distribution company specializing in soft drinks, principally soda products, along with a selection of other non-carbonated beverages and purified water. The company operates multiple production facilities and warehouses across the central United States. As a key player in the Food & Beverage industry, particularly in shipping and logistics, the company has continuously sought to optimize its operations to meet evolving market demands.

Project Objective

The company aimed to upgrade its network infrastructure to support its bottle lines in manufacturing and, secondarily, to enhance the warehouse distribution network. Prior to the upgrade, the existing network was being pushed to its maximum capacity, frequently experiencing failures that negatively impacted production and fulfillment operations. These network outages led to costly downtime, disrupting manufacturing processes and delaying shipments. The goal of the project was to establish a robust, modern IT network with tight integration with the OT (Operational Technology) network to increase visibility, actionable data insights, and enhanced security measures to ensure seamless, uninterrupted operations.

Solution Overview

To achieve these objectives, the company implemented Cisco Catalyst 9300 IE switches. The Catalyst 9300 IE Series is a leading stackable enterprise access switching platform designed to transform network capabilities for a hybrid work environment. As part of the Catalyst 9000 family, these switches offer robust performance, security enhancements, and exceptional user experience. This solution allows for seamless connections, reinforced security, and redefined operational efficiency across the company’s facilities.

The Catalyst 9300 IE switch was chosen for its unique flexibility and modular design. The switch supports modular 10G and 1G uplinks, making it adaptable to varying network demands across the companies production and warehouse facilities. This flexibility ensured that the infrastructure could support both current and future growth in network capacity, while also allowing for easy upgrades as operational requirements evolved.

The Catalyst modular architecture provided the ability to scale with minimal disruption, a critical factor for the uninterrupted operations of both the bottling lines and distribution networks. The switches’ ability to integrate easily with existing infrastructure and support multiple bandwidth requirements was essential in ensuring the seamless flow of production data and logistics information across multiple locations.

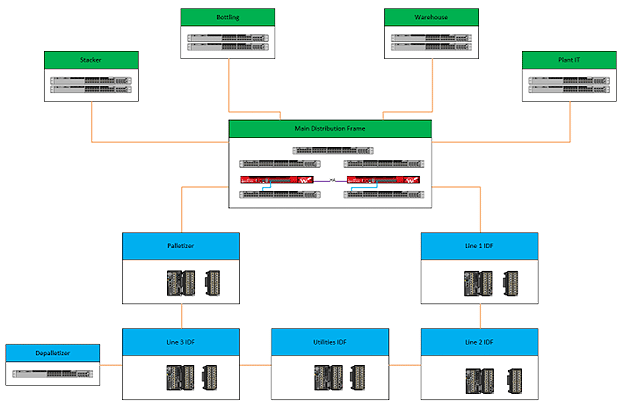

Beyond performance, Industrial Networking Solutions (INS) also addressed power redundancy at each facility by adding dual power supplies per switch and implementing power stacking when using a stack configuration. The switches are powered by both Uninterruptible Power Supplies (UPS) and facility power, ensuring continuous uptime even in the event of a power failure. The original infrastructure at the facilities were primarily a copper daisy-chain topology, which presented significant challenges due to frequent failures and the lack of redundancy. These limitations often resulted in network outages that disrupted production and fulfillment operations. To address these issues, INS deployed single-mode fiber to all IDFs in a physical star configuration, significantly improving network reliability and capacity. Additionally, a REP (Resilient Ethernet Protocol) ring was implemented in the MDF, providing critical redundancy to the OT network for a fault tolerant architecture.

The deployment of the Cisco Catalyst 9300 IE switches, along with the significant infrastructure upgrades, was supported by INS through a comprehensive range of services tailored to meet this companies specific needs. These services included network design and planning, installation and configuration, and ongoing support and maintenance to ensure optimal performance and reliability.

Reasons for Choosing Cisco

Reasons Cisco was chosen to modernize the network and strengthen manufacturing and distribution:

- IT/OT Convergence: Cisco offers comprehensive solutions that converge IT and OT environments, providing an end-to-end solution that ensures seamless integration and management.

- Modern OT Network Requirements: The OT operations team for the facilities was focused on deploying a modern network infrastructure that provides visibility, actionable data insights, and hardened security.

- Reliability and Network Uptime: Cisco’s solutions deliver high reliability, consistent network uptime, improved latency, and reduced cybersecurity risks, all of which were critical to the companies operational needs.

Role of Industrial Networking Solutions (INS)

INS played a pivotal role in the successful implementation of the Cisco solution. INS’s deep expertise in both IT and OT environments and strong relationships with this beverage company’s leadership team ensured a smooth and effective deployment. INS provided critical support from the initial network audit through to the final implementation and ongoing maintenance, delivering a tailored solution meeting the customer’s operational objectives.

A comprehensive network audit revealed the need for a holistic approach, bridging the OT network back into the campus and HQ IT infrastructure. The existing non-Cisco products on both the IT and OT sides presented an opportunity for displacement with Cisco’s advanced solutions, ensuring a more cohesive and secure network environment.

Results and Benefits

- Performance Improvements: The implementation of Cisco Catalyst 9300 IE switches resulted in significant performance enhancements, including increased network speed and reduced downtime. This was especially crucial for both the manufacturing and distribution operations, where consistent, real-time data flow was needed to optimize production and shipping processes.

- Operational Efficiency: With the modernized network infrastructure, the company experienced more streamlined operations across its facilities. The previous frequent network outages that hampered production were eliminated, and the enhanced network uptime allowed the company to maintain a more reliable workflow. The distribution network also benefited, with trucks rolling out on time and shipping schedules running smoothly due to the stable, uninterrupted flow of information between manufacturing and logistics teams. The improved network performance also facilitated seamless pallet scanning during truck loading, ensuring accurate and efficient tracking of products and further improving fulfillment accuracy and speed.

- Return on Investment (ROI): The investment in Cisco technology delivered a strong ROI by reducing operational costs associated with network failures, downtime, and maintenance. The increased reliability of the network ensured that both production and logistics operations ran efficiently. By optimizing pallet scans during truck loading and ensuring real-time data transfer, the company significantly reduced errors in shipping, leading to enhanced customer satisfaction and overall business growth.

Architecture

Conclusion

The successful network modernization project at this beverage company highlights the strategic importance of leveraging advanced technology to drive operational excellence in the Food & Beverage industry. By partnering with INS and adopting Cisco’s innovative solutions, they achieved significant improvements in operational efficiency, allowing for smoother production workflows and more reliable logistics operations. The enhanced network infrastructure provided by Cisco Catalyst 9300 IE switches also strengthened their cybersecurity posture, reducing vulnerabilities and safeguarding critical manufacturing and distribution data from potential threats.

Initially, there was some apprehension at the company’s various locations about the network overhaul and the assistance provided by INS. However, as the results of the first deployment became evident—improved network uptime, streamlined pallet scanning, and smoother shipping processes—the other facilities began implementing network upgrades across their enterprise. The successful implementation at one site transformed into a model that other locations sought to replicate.

These advancements have not only optimized this company’s operational capabilities but have also created a more secure and resilient environment, positioning the company to adapt swiftly to future market changes and challenges. By investing in a robust and secure network foundation, they are better equipped to ensure sustained growth, maintain high levels of customer satisfaction, and achieve their long-term strategic goals.