Networking Partnerships Drive Success

Overcoming Connectivity Challenges at Remote Renewable Energy Sites to Enable Reliable Data Access and Optimize Operations

Challenge

Renewable energy sources, like solar farms and wind generation sites, are rich data sources due to their highly instrumented and automated nature, but their remote locations often make it difficult to access the information.

Solution

The application calls for industrial-grade IoT gateways, which are typically ARM-based computers. These computers need various wired and wireless networking provisions, and they are interconnected with managed and unmanaged switches. All devices need to be ruggedized versions able to operate in the temperature ranges expected at renewable site locations. Based on these criteria, the team chooses several products from the expansive Moxa portfolio.

Result

INS, with its established supply chain services can support their partners not only with products, but also with design, assembly, testing, and shipping to site, resulting in reduced time to deployment and minimized overall labor costs. As the direct client, Power Factors benefits from its ability to provide a complete solution delivered right to their end users. In turn, each end user receives ready-to-operate kitted hardware, configured for plug-and-play operation.

A cloud software solutions provider teams with an IoT value-added reseller for hardware, networking, and services, enabling each party to focus on their strengths and deliver a complete asset management solution to their mutual clients. Renewable energy sources, such as wind, solar, and storage share several challenges from a digital transformation standpoint. One advantage of these highly instrumented and automated installations is their richness as data sources, with data originating from inverters, meters, weather stations, trackers, power distribution equipment, and more. This data is essential for operating, optimizing, and maintaining energy production. However, renewables sites are often located in remote areas, which can present difficulties when trying to send data home to the cloud.

The growing number of intelligent field devices and Internet of things (IoT) connectivity options are providing new possibilities. However, just choosing a computing platform, or making a single wireless connection, is not enough to effectively access and act upon field data. Comprehensive data solutions involve careful selection and integration of many technologies for networking, data transport, and storage, analysis, and cloud computing. Scalability of the overall design is another key concern.

It is difficult for any company to be an expert in every aspect for remotely accessing and handling such data sources. However, renewable energy producers are finding they can partner with specialists and then leverage their collective expertise to supply specific portions of a project. This enables the companies to build out and provide a complete solution with the required capability, reliability, and supportability.

Harmonizing clean energy assets

The number of renewable energy assets is increasing rapidly. Widely dispersed solar, wind, hydro, and storage operations typically use a variety of systems and tools for supervisory control and data acquisition (SCADA), analytics, reporting, and other operational and maintenance needs. But for asset owners, power producers, and their service providers, there is a great need to accomplish these tasks and more under a fully integrated digital platform. A comprehensive system also must incorporate work order management, contract compliance, and market integration, even enabling virtual power plant (VPP) operation in some instances. Power Factors provides mission-critical software and services to their clients in the clean energy arena. Among several offerings is a cloud-based asset management software solution, with features making it ideal for renewable energy plant operators to monitor and manage energy output and overall performance.

Power Factors offers cloud-based asset management software solutions for the fast-growing renewable energy sector. While much of the software runs on the cloud, there is a great need for industrial grade local computing and robust networking.

Early in the process, it became clear that collecting, integrating, and acting on so many remote data sources would require many different products and services provided by multiple vendors, including:

- Robust on-site computing resources.

- Networking connectivity using wired Ethernet, Wi-Fi, and a secure cellular WAN.

- Seamless connectivity with cloud storage and computing resources.

- Built-in cybersecurity throughout.

- A vigorous version-control methodology for all hardware and software platforms.

- Provisions for streamlining deployments and validating functionality. Hydro Energy Energy Storage (Cloud-based asset management software solution)

Power Factors excels in many of these aspects, especially in creating an open, smart, and autonomous cloud platform. To help establish a cost effective data acquisition solution for commercial & industrial (C&I) and distributed generation (DG) systems, Power Factors sought a proven partner to help provide the networking, edge compute, and WAN connectivity components of their solution.

Team Solutions

As a leader in both enterprise and industrial IoT solutions, Industrial Networking Solutions (INS) has provided products, support, and engineering services to their clients since 1998. This space has evolved from basic industrial Ethernet, to machine-to-machine (M2M) connectivity, and now wired and wireless IoT solutions. INS is a value-added reseller (VAR) offering best-in-class IOT networking technologies, and an engineering team versed in the specific needs of operational technology (OT) installations.

INS provides value as part of a networking solution team by:

- Bundling industrial-grade hardware products.

- Furnishing panel assembly services.

- Facilitating cellular connectivity.

- Providing engineering services, acceptance testing and configuration validation.

Power Factors engages INS to supply complete connectivity platforms for gathering remote field data from solar power generating facilities. Based on other industry successes, INS knows the key elements and features necessary to design, test, install, and commission this type of system.

The application calls for industrial-grade IoT gateways, which are typically ARM-based computers. These computers need various wired and wireless networking provisions and they are interconnected with managed and unmanaged switches. All devices need to be ruggedized versions able to operate in the temperature ranges expected at renewable site locations.

Based on these criteria, the INS team chooses several products from the expansive Moxa portfolio. For over 30 years, Moxa has specialized in networking, connectivity, and computing solutions for rugged and industrial use. The overall product line includes many different form factors of Ethernet switches, security devices, radios, media converters, and associated modules. Also available are industrial computers, IoT gateways, video encoders, wired I/O and serial/USB connectivity, power supplies, and network management software.

INS specifies these Moxa products for the Power Factors solutions:

- Moxa UC-8112A-ME-T-LX

An ARM IIoT gateway, with one Mini PCIe expansion slot available for a user-selected cellular wireless module. This embedded computer configuration is optimized for energy monitoring systems, and it has flexible interface options for RS-232/422/485 serial and 10/100 Mbps Ethernet commonly found in the field. - Moxa UC-3111-T-US-LX

An ARM IIoT gateway, with built-in LTE Cat. 1, Wi-Fi, and Bluetooth. - Moxa EDS-208A-T

An unmanaged Ethernet switch built to operate reliably in the harshest field conditions and using store-and-forward processing with protection against broadcast storms.

In most instances, the Moxa UC-3100 gateway with integrated LTE cellular WAN connection is utilized, but in some cases, the Moxa UC-8100 is deployed and paired with a separate piece of hardware for cellular connectivity.

As a full-service VAR representing Moxa and other complementary manufacturers, INS has deep knowledge of Moxa devices, and other components required for field-rated control/computing panels, such as power supplies, protocol converters, cabling, radios, and more. INS can also assemble the components into an appropriate panel and factory test them prior to shipment.

INS maintains ready access to all the Moxa and other parts needed for control panels, and it operates an assembly shop to build and test them.

INS procures components and assembles the panels, provides space in its lab to stage and configure them with the applications supplied by Power Factors, and performs the factory testing and validation needed for panels assigned to each remote site.

Once complete, the application-ready systems are shipped to solar plant operators for a turnkey installation. A robust operational process was implemented to ensure efficient replication upon each subsequent order.

This arrangement significantly unburdens the Power Factors team from the time- and space consuming logistics associated with these tasks and provides a force multiplier for Power Factors personnel who can now focus on other aspects of their services.

Responsive Architecture

Fundamental to Power Factors and many IoT applications is the need to develop an architecture supporting various goals that are sometimes at odds with each other. The right architecture delivers responsive insights supporting action, reduces operational costs, and maintains security for critical infrastructure associated with energy. Any missteps in the architecture could make the system slow, expensive, and vulnerable to security threats.

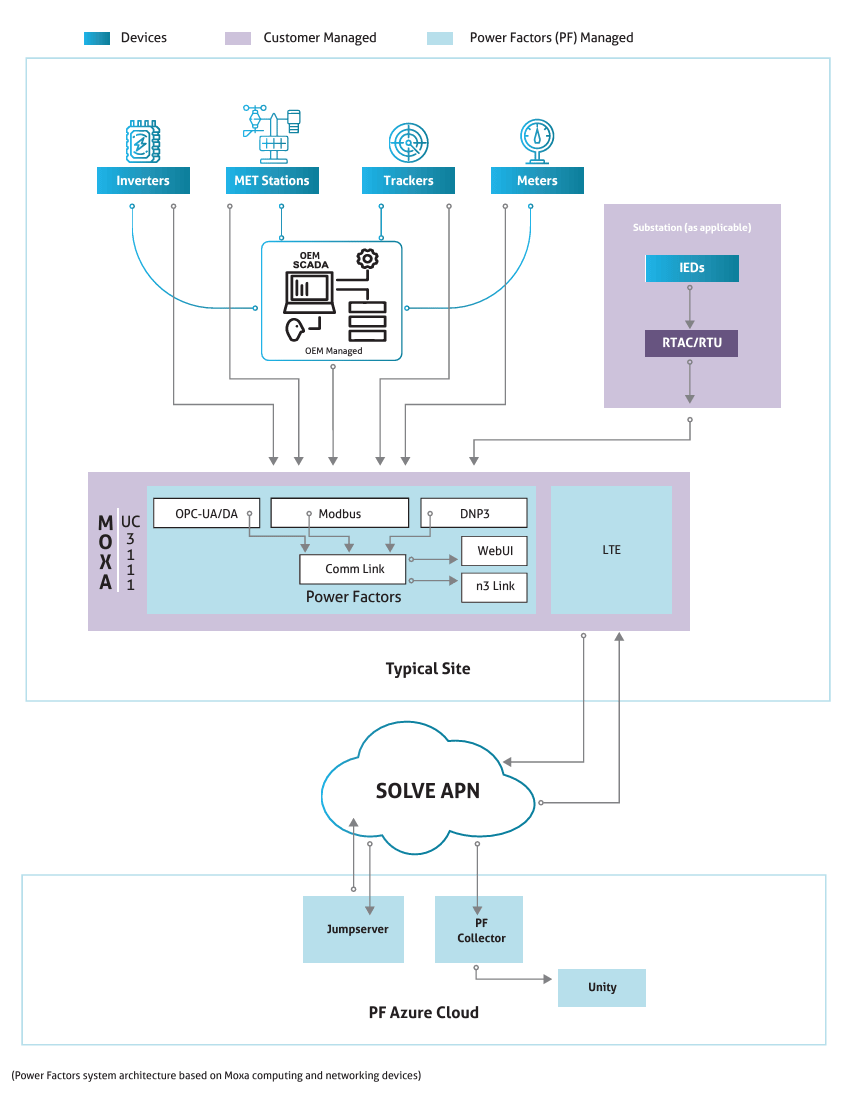

Power Factors has an edge architecture that utilizes Moxa computing, commercial & industrial (C&I), or Distributed Generation (DG) assets, providing the necessary preprocessing capability close to the data sources to minimize the volume of upstream communication to the overall cloud solution.

Moxa computing solutions allow portions of the Power Factors application to operate close to the data sources for reduced latency by providing crucial preprocessing to minimize the required volume of WAN data transportation. The typical conditions at each site range widely, and can be a new installation, a partial retrofit, or a complete “rip-and-replace” scenario. The IoT panel designs are standardized for maximum efficiency, and INS customizes the basic concept as needed to fit varying end-user requirements. From site, data is aggregated and transmitted to the Power Factors Cloud environment, typically via a secure cellular WAN connection using a private APN, with each site segregated as required to maintain a high level of security.

For the vital cellular WAN connectivity, INS partner Solve Networks, a mobile virtual network operator (MVNO) specializing in IOT cellular connectivity, provides the affordable data plans and secure data transportation to the cloud servers. Initiating and managing cellular contracts for each remote site can be time-consuming for those unfamiliar with “lighting up” a secure cellular WAN. Solve and INS handle this process seamlessly and ensure all provisioning occurs in advance at INS during staging.

This initial provisioning means that at the INS facility each panel is connected to the cellular network automatically as it is energized, enabling rapid verification by the team. Similarly, when the tested IoT panels are sent to the field and installed, each one can simply be energized, and it will connect automatically to the Power Factors cloud solution.

Results

At its core, Power Factors is a software company with extensive expertise and innovative management tools for the renewable energy industry. Power Factors delivers asset owners and their operators and service providers in this sector a best-in-class digital asset management system. Their cloud solution relies on secure and reliable computing hardware and networking to connect with a variety of remotely located sites.

Partnering with INS enables the Power Factors team to focus on their core capabilities, confident that INS will supply, test, and deploy the necessary high-performance and cost-effective hardware and networking foundations needed. For the control panels required by the cloud solution, INS maintains a focus on following high levels of standardization and streamlining the provisioning process, while allowing portions of the work to be customized as needed. INS can also provide ongoing support, including any required software updates or modifications.

This is a prime example of how VARs like INS can support their partners not only with products, but also with design, assembly, testing, and shipping to the site, resulting in reduced time to deployment and minimized overall labor costs. Power Factors benefits from INS’s ability to provide a complete solution ready to work “out of the box” at the end users’ sites. In turn, each end user site receives ready-to-operate kitted hardware that is ready for plug-and-play operation of the Power Factors system.

Case Study Partners

Power Factors

Moxa